MAKING A SUPERIOR PRODUCT - CATENA LTD. Official dealer Berco Spa.

Main menu:

MAKING A SUPERIOR PRODUCT

About Berco

ADDING VALUE TO YOUR BUSINESS

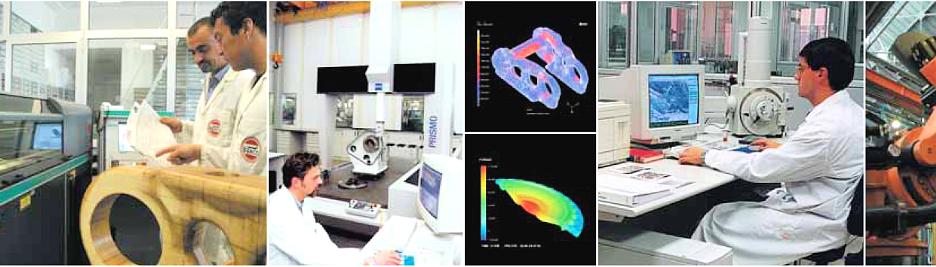

State-of-the-art 3D modeling, Finite Element Analysis

(FEM) and Rapid Prototyping enables to design,

optimize and evaluate a component before it is built.

Artificial Intelligence techniques are currently being

developed to automatically inspect 100% of

components. Reliability Test on components are

carried out to determine life and performance in a

variety of field applications.

Berco Metallurgy Laboratory employs advanced

machines such as an electron microscope with

microanalysis, a spectrophotometer, tribometers for

wear tests, MTS presses for static and fatigue tests

(also at extreme temperatures -70°C ÷ 250°C) on

materials and components.

Huge efforts are also devoted to the development of

New Materials and improvement of the Heat Treating

Processes, to guarantee longer product life and

superior products.

Photo-elasticity and Strain Gauge techniques are

commonly used for stress and fatigue analysis on

individual and assembled components.

Berco adds value not only to the products

but also to Your Business.