BSD - SERVICE DIVISION - CATENA LTD. Official dealer Berco Spa.

Main menu:

BSD - SERVICE DIVISION

Our offerings

The Berco Service Division offers a complete

solution to your undercarriage maintenance

needs, with a range of specific operations

including pin & bushing turning, roller lubrication,

track shoe fastening or on-site machine servicing.

Superior engineering and technology,

comprehensive know-how and state-of-the-art

manufacturing ensure the total quality of the

equipment offered.

Berco offers turnkey solutions, custom-made

design and supply of complete workshop and

repair facilities, training and technical

support.

DCL/DCL-D Lubrication Device | |

| OPERATING SPECS | |

| Max. vacuum | 759 mm/Hg 29.88”Hg |

| Vacuum pump capacity at atm. pressure | 66 dm3/min |

| Oil pump max. delivery | 3 dm3/min 183 in3/min |

| Pressure setting | 3 bar 43 lbf/in2 |

| Oil tank capacity | 75 dm3 2.6 ft3 |

DCL/DCL-D Lubrication Device

Moving Your bussiness ahead.

THE WIDEST CHOICE

• PT350 stationary hydraulic press for the assembly/disassembly of medium and large-size track chains (e.g. Komatsu D575, O&K RH120C, Liebherr R994B and Caterpillar D11 track chains)• PT250 stationary hydraulic press for medium and small-size chains• PP50 and PP100 portable presses powerful and versatile tools for assembly and disassembly of track chains, sprockets, rollers, shafts, transmission components, etc…• Complete line of tools for servicing various undercarriage sizes, available upon request•DCL and DCL-D track control and lubricating devices for checking the vacuum in oil seals and injecting oil into lubricated chains, rollers and idlers (DCL-D model)•CEM7000 electromechanical track shoe wrench for screwing and unscrewing the shoe bolts on tracked vehicle chains, both large and small. The electronic “torque-turn” control ensures highly reliable and consistent bolt torquing results. The high torque developed facilitates bolt removal even in the most difficult situations (e.g. rust)• The ACC track winder is designed for winding medium and small-size chains, whereas the ACC/S is specifically designed for the larger sizes

| CEM7000 Electromechanical Wrench | |

| OPERATING SPECS | |

| Max. torque on socket shaft | 7,000 N•m 5,160 lbf•ft |

| Max. final tightening angle | 360° |

| Socket shaft rotation speeds (2-speed), in either direction | 8.5-145 rpm |

| Socket shaft motor power | 6 HP 4.5 kW |

| Max. admitted width track chain + shoes | 1,200 mm |

| Max. admitted height track chain + shoes | 370 mm |

CEM7000 Electromechanical Wrench

| ACC-ACC/S Track Winders | ||

| OPERATING SPECS | АСС | АСС/S |

| Max output torque | 6600 Н.м | 9100 Н.м |

| Motor rating | 4 HP 3 kW | 4 HP 3 kW |

| Max. mass admitted onto spindle | 3,600 kg | 6,000 kg |

| Max track shoe width admitted (with optional device) | 762 (1,000) mm | 1,460 mm |

ACC-ACC/S Track Winders

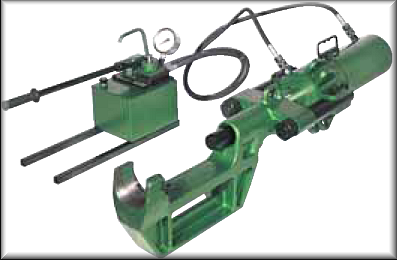

| PP100-PP50 Portable Hydraulic Track Presses | ||

| OPERATING SPECS | РР100 | РР50 |

| Max. ram force | 911.4 kN (93 tf) | 490 kN (50 tf) |

| Max. traction of rams | 715.4 kN (73 tf) | 323.4 kN (33 tf) |

| Max. operating pressure | 70 Mpa (700 bar) | 70 Mpa (700 bar) |

| Max. ram stroke | 350 mm | 280 mm |

| Oil capacity | 4.64 dm3 | 2.00 dm3 |

PP100-PP50 Portable Hydraulic Track Presses

| PT250-PT350 Hydraulic Track Presses | ||

| OPERATING SPECS | РТ250 | РТ350 |

| Max ram force | 1,803 kN (184 tf) | 3,185 kN(325 tf) |

| Max operating pressure | 31.5 Mpa (315 bar) | 35 Mpa (350 bar) |

| Макс. давление | 70 мПа (700 бар) | 70 мПа (700 бар) |

| Ram rod diameter | 230 mm | 270 mm |

| Max ram stroke | 160 мм | 190 мм |

PT250-PT350 Hydraulic Track Presses