BTS - COMPLETE TRACK SYSTEMS - CATENA LTD. Official dealer Berco Spa.

Main menu:

BTS - COMPLETE TRACK SYSTEMS

Our offerings

The Berco Complete Track Systems division is the ideal

solution for all OEMs that now, more than ever, are

expressing the need for complete 'turnkey' undercarriage

systems.

Berco is able to supply compete track systems

(undercarriage components, hydraulics, frames and

gearboxes), finished and ready for installation on

machines directly on manufacturers' own assembly lines.

Berco has a vast range of products and, when requested

for special applications, develops sets of components

specifically tailored to customers' needs.

All this makes Berco a supplier with a level of reliability

and skill that clearly distinguishes them from other

systems integrators, who merely find general

components on the market and 'put them together'.

Berco Complete Track Systems is able to supply safe,

reliable systems, soundly based on the hallmark

characteristics of the Berco brand: extensive know-how,

flexible design responding rapidly and effectively to

customers' needs and, finally, the ability to support the

customer at every stage, from design right through to

installation.

Berco's great competence and flexibility in engineering

and production allow them to develop, design and supply

undercarriage systems for a wide range of applications,

such as pavers, rock boring machines, rice and sugarcane

combine harvesters, mini-excavators, etc.

The Berco Complete Track Systems engineering staff use

the same calculation methods in the development of new

machines in co-engineering projects with OEMs as in the

design and verification of the welded structures in their

own production systems. These methods include FEM

analysis on frames, dynamic and vibrational analysis,

CAD-3D design and construction drawings for

production. All this guarantees high quality standards

and the ability to satisfy even the most exacting and

complex needs of the customer.

These solid engineering skills are combined with a

remarkable production capability, now spread over five

factories and characterised by leading edge technology

and highly automated production lines.

This production capability guarantees the quality

demanded by the customer, on schedule.

Finally, a continuously expanding network of branches,

strategically located all over the world, is able to supply

on a just-in-time basis and guarantee a speedy and

efficient after-sales service.

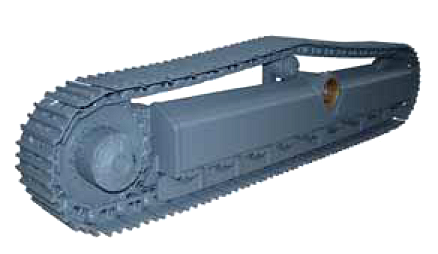

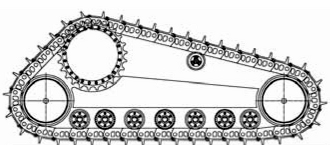

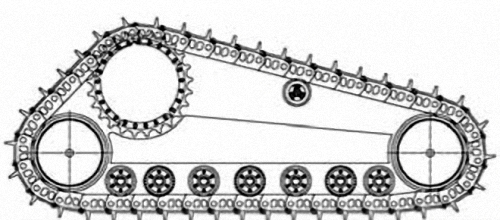

GENERIC UNDERCARRIAGE FRAMES

• Standard layout dimensions are presented• Custom-tailored design on request• Sideframe or carbody supply• Wide choice of gear-boxes and hydraulic motors isavailable• Optional swing bearing plate and swivel joints areavailable

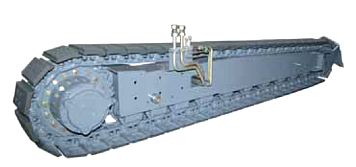

DRILLING RIG FRAMES

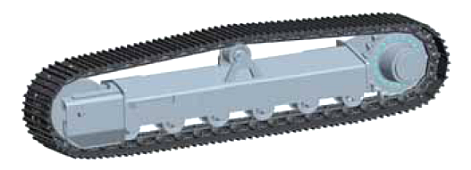

ASPHALT PAVERS

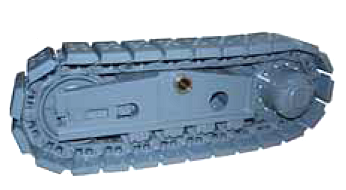

MOBILE CRUSHING PLANT FRAMES

• Standard layout dimensions are presented• Custom-tailored design on request• Sideframe or carbody supply• Wide choice of gear-boxes and hydraulic motors isavailable• Optional swing bearing plate and swivel joints areavailable• Standard layout dimensions are shown• Custom-tailored design on request• Wide choice of gear-boxes and hydraulic motors isavailable

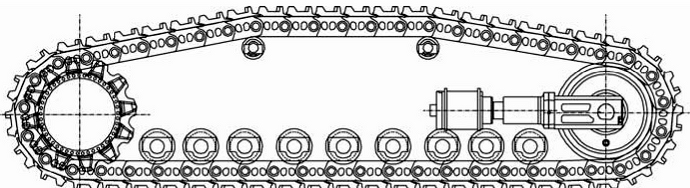

ROAD MILLING MACHINES

MINI EXCAVATORS

| CLASS Т150 Pitch: 90 ММ |  | CLASS D5M Pitch: 171,5 ММ |

| CLASS Т300 Pitch: 101,6 ММ |  | CLASS D6M Pitch: 190 ММ |

| CLASS F25C Pitch: 125 ММ |  | CLASS D6R Pitch: 203,2 ММ |

| CLASS T500 Pitch: 135 ММ |  | CLASS D7N/R ШАГ: 215,9 ММ |

| CLASS FL4 Pitch: 140 ММ |  | CLASS D8N/R Pitch: 215,9 ММ |

| CLASS D3-D4 B/C Pitch: 155,5 ММ |  | CLASS D8K-D155 Pitch: 228Б6 ММ |

| CLASS D9N/R - D275 Pitch: 240,0 ММ | ||

| CLASS D10N/R Pitch: 260,0 ММ | ||

| CLASS D11N/R - D475 Pitch: 317,5 ММ | ||

| |||

300 TON CLASS EXCAVATOR Pitch: 350 ММ | |||