Hydraulic portable presses Berco - CATENA LTD. Official dealer Berco Spa.

Main menu:

Hydraulic portable presses Berco

Our offerings

РР 50

РР 100

Assembly and disassembly track chains - a full set of equipment.

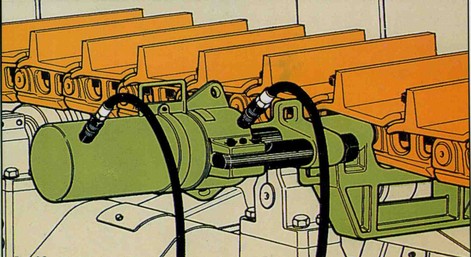

In the sector of road construction (bulldozers and excavators) technology is particularly strong demand versatile equipment to a minimum effort and quickly from the mechanics to carry out work on the assembling and dismantling of crawler chains, drive wheels, rollers, shafts, transmission components, etc. With the new series of portable hydraulic presses "PP" and related equipment, specially designed for this sector, the company «Berco» offers users a wide range of special equipment and interchangeable components for different models of tracked vehicles as the national production and foreign. The equipment included a series of "PP" for working with tracked chains consists of hydraulic presses PP 50 and PP 100 sovmestno snap the base (Figure 4, 5, 6, 7)

РР 50

Hydraulic press comprising:

Hydraulic press comprising:

- Hand pump PM 2 (or electric pump PE 1)- Cylinder double acting SR 50 with a force pushing up to 50 tons- 2 flexible pipeline;- 2 quick disconnect couplings on the pipeline;- 2 quick disconnect couplings on the cylinder;

Hydraulic Press

Fig.1

РР 50

РР 50

PP 50 S

PP 100A complete set of equipment for the installation and dismantling of track pins and bushings as a normal connection and consists of:- Hydraulic press PP 50 (cylinder + hand pump)- Snap-base S 50, with support in the form of a "C"

Hydraulic press comprising:- Hand pump PM 2 (or electric pump PE 1)- Cylinder double acting SR 100 with a force pushing up to 100 tons- 2 flexible pipeline;- 2 quick disconnect couplings on the pipeline;- 2 quick disconnect couplings on the cylinder;

Hydraulic Press

Fig.2

РР 50 S

РР 50 S

РР 100 S

A complete set of equipment for the installation and dismantling of track pins and bushings as a normal connection and consists of:- Hydraulic press PP 100 (cylinder + hand pump)- Snap-base S 100, with support in the form of a "C"

PP 50 G

PP 100 GA complete set of equipment for the installation and dismantling of track pins and bushings as a normal connection and consists of:- Hydraulic press PP 50 (cylinder + hand pump)- Snap-base G 50, with the yoke

full set of equipment for assembly and disassembly of track pins and bushings as a normal connection and consists of:- Hydraulic press PP 100 (cylinder + hand pump)- Snap-base G 100, a yoke

Hydraulic Press

Fig.3

РР 50 G

РР 50 G

BASIC EQUIPMENT FOR TRACK CIRCUITS - Press PP 50 / PP 100

Attachments consists of a solid packing in the form of a "C", the two rods, a sleeve and two nuts. The special shape of the nozzle allows for fast and reliable operation of the recess and insert track pins and bushings in all operating conditions, even with established shoes. It can be used to force the recess 50 tons. The approximate weight of 44 kg.

Basic equipment for track chain

Fig.4

S 50

S 50

Accessories consists of two rods, the movable yoke, 6 pcs. spacers and two nuts. This is a traditional snap when you use allows you to quickly and reliably operations recess and inserting Track pins and bushings in all operating conditions, even with established shoes. It can be used to force the recess 50 tons. The approximate weight of 29 kg.

Basic equipment for track chain

Fig.5

G 50

G 50

Attachments consists of a solid packing in the form of a "C", the two rods, a sleeve and two nuts. The special shape of the nozzle allows for fast and reliable operation of the recess and insert track pins and bushings in all operating conditions, even with established shoes. It can be used up to 100 tons of digging forces. The approximate weight of 92 kg.

Basic equipment for track chain

Fig.6

S 100

S 100

Accessories consists of two rods, the movable yoke, two fingers with pins. This is a traditional snap when you use allows you to quickly and reliably operations recess and inserting Track pins and bushings in all operating conditions, even with established shoes. It can be used up to 100 tons of digging forces. The approximate weight of 60 kg.

Basic equipment for track chain

Fig.7

G 100

G 100

Depending on the type of work on the track chain and the machine model, the equipment must be used with specific additional equipment, i.e. bushings, spacers, pushers, etc. Their choice should be made depending on the type of the tracks.

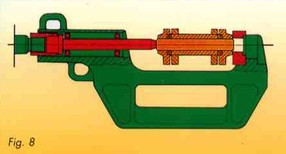

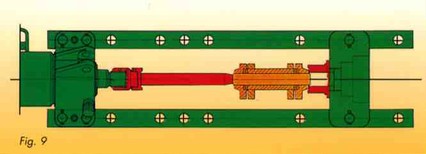

The diagrams Ris.8.i Fig.9 considered the location of equipment for excavation finger of track chain: in red highlighted additional equipment for the appropriate circuit. In a similar manner as is done with the help of additional equipment insertion and removal of plugs.

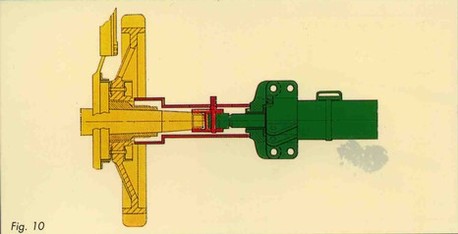

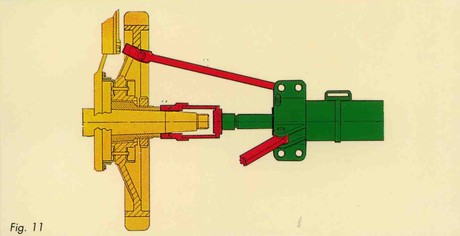

Figures 10 and 11 demonstrate the installation and removal of suspended wheels track chain with the help of additional equipment, highlighted in red.

Pumps and cylinders.

Pumps

Designation RM 2 and PE 1 is identified without flexible pipes and quick action clamps as shown in The following specific photo. Pipelines and clips are available separately on request.

Used as an alternative pump PM 2; in this case the hydraulic press with these pumps are designated 50 and the PPE PPE 100. The two-step process, with automatic transition from the first stage to the second stage. Includes 4-way hand-lever valve with 3 position with a pressure gauge, an internal safety valve, set during installation to the maximum working pressure indicator and the valve on the outside of all intermediate pressure, depending on the job requirements.

Ability to work in continuous cycle with pressure up to 500 bar in intermittent cycle for 6 minutes before the maximum working pressure. The ability to start the engine in a closed hydraulic circuit under pressure. The maximum pressure of 700 bar oil flow 0.85 dm3 per minute.

Fuel tank capacity of 16 dm3.

Engine power 1.1 kW.

The approximate weight of 45 kg without oil.

PUMP

Figure 13 2 PM - hand pump

Used in two hydraulic presses where necessary force of 50 tons and 100 tons. Operation takes place in two stages pressurizing with automatic transition from the first to the second stage. This pump includes a 4-way manual valve lever at 3 positions and gauge.

The maximum pressure of 700 bar with a capacity for one time injection of 0.005 dm3 (5 mL).

The lowest pressure of 14 bar with a capacity of 1 times forcing 0,124 dm3 (124 ml).

Fuel tank capacity of 7.5 dm3 (liters).

Approximate weight without oil about 21.5 kg.

PUMP

Figure 14. PE 1 electric pump

Cylinders.

Double acting cylinders that make up the hydraulic presses PP50 RR100 and manufactured in accordance with the latest design and technology. Significant progress guide enables non-disruptive operations for assembling and dismantling the track circuit. Cylinder heads and pusher tips include the use of necessary equipment for various operations. Two quick connections on the side of the cylinder, which you see in the photos are available on request.

The maximum pressure of 700 bar

The maximum ejection force 50 tons

The maximum pulling force of 33 tons

The maximum stroke of the pusher 280 mm

Oil volume 2 dm3

Approximate weight 44.2 kg

CYLINDER

СР 50

The maximum pressure of 700 bar

The maximum ejection force 93 tons

The maximum pulling force 73 tons

The maximum stroke of the pusher 350 mm

Oil volume 4.64 dm3

The approximate weight of 82 kg

CYLINDER

СР 100